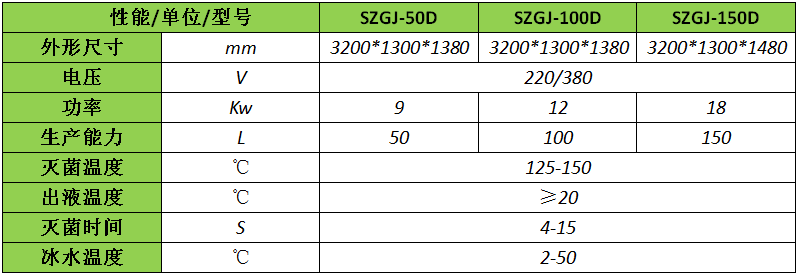

該設備已投放多個城市。是大中院校、科研院所 、企業實驗室 、奶吧的産品小試或中試專用設備 。适用于果蔬飲料等産品的UHT超高溫殺菌工藝。

1、自動進料-消毒-剪切化料-調配-滅菌-冰水速冷-灌裝-CIP清洗-灌裝全自動一鍵式操作。

2、采用進口電腦程序控制系統和電器配件,觸摸屏人機界面(miàn)

3、UHT超高溫滅菌功能(néng)●剪切化料及調配功能(néng)●管道(dào)消毒功能(néng)●CIP自動清洗功能(néng)●冰水制冷(低溫速冷)●具有二次熱回收功能(néng)、熱利用率高

4、采用液态相變技術,确保産品無結垢、挂壁、褐變、焦糊等質量問題;

具有自動控溫調節、上下限報警、溫度在線跟蹤、8位溫度檢測曲線圖象顯示、自動控制運行與監控功能(néng),便于教學。

5、該設備工藝流程和産品工藝流程與工廠接近,技術路線及工藝控制參數與工廠參數相同

The equipment is my company's first domestic product, has been put a number of cities. Is a large and medium-sized institutions, research institutes, enterprise laboratories, milk bar products, small test or pilot special equipment .Applicable to fruit and vegetable drinks and other products UHT ultra-high temperature sterilization process.

1, automatic feeding - disinfection - shear material - deployment - sterilization - ice water speed cold - filling - CCI cleaning - filling automatic one - button operation.

2, the use of imported computer program control system and electrical accessories, touch screen man-machine interface

3, UHT ultra-high temperature sterilization function●shear material and deployment of the function●pipeline disinfection●CIP automatic cleaning function●ice water cooling (low temperature cold) ●with secondary heat recovery function, high heat utilization

4, the use of liquid phase change technology to ensure that products without scaling, wall, browning, coke and other quality problems; With automatic temperature control, upper and lower limit alarm, temperature online tracking, 8-bit temperature detection curve image display, automatic control operation and monitoring functions, easy to teach

5, the equipment process and product process and factory close to the technical route and process control parameters and factory parameters the same

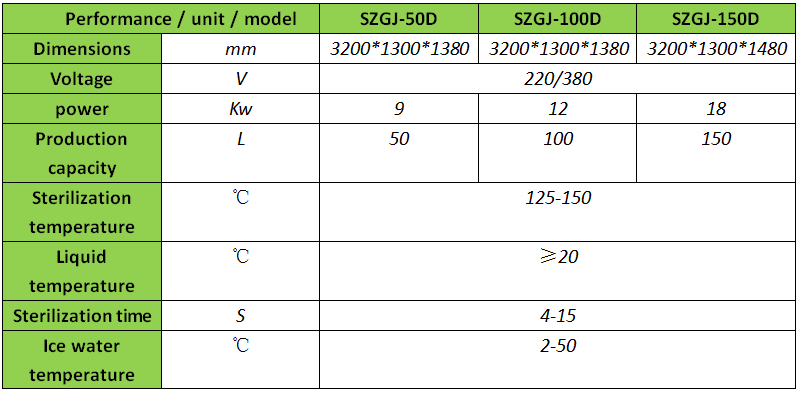

|