該機組加熱方式分爲蒸汽加熱和電加熱兩種選擇,廣泛适用于保質期長的純牛奶、鮮牛奶、豆奶花色奶、乳飲料、巴氏奶、酸奶、各種果汁飲料、醬油(醋)、葡萄酒、啤酒、藥用積液的巴氏殺菌、超巴氏殺菌、UHT超高溫殺菌。

●具有自消毒程序、生産程序、CIP清洗程序的全過程控制運行及監控,基本實現無人值守

●全部采用進口PLC程序控制器、觸摸屏人機界面(miàn)、施耐德電氣 原件、斯派莎克蒸汽閥組、衛生級氣動(電磁)閥組

●具有均質功能(néng)

●預殺菌功能(néng)

●CIP清洗功能(néng)

●管道(dào)消毒功能(néng)

●具有冰水(冷水)冷卻功能(néng)

●機組與灌裝機直連和控制系統相互通訊功能(néng)

●滿足多産品、多工藝參數、多生産能(néng)力的轉換和不同的滅菌溫度要求

The heating method of the unit is divided into steam heating and electric heating two kinds of options, widely used in long shelf life of pure milk, fresh milk, soy milk color milk, milk drinks, pasteurized milk, yogurt, all kinds of fruit juice drinks, Wine, beer, medicinal effluent pasteurization, ultra-pasteurization, UHT ultra-high temperature sterilization.

●With the self-disinfection procedures, production procedures, CIP cleaning procedures for the whole process of control operation and monitoring, the basic realization of unattended

●all imported PLC program controller, touch screen man-machine interface, Schneider Electric original, Spirax Sarco steam valve group, Hygienic pneumatic (electromagnetic) valve group

● with homogeneous function

●pre-sterilization function

●CIP cleaning function

●pipeline disinfection

●with ice water (cold water) cooling function

●unit and filling machine direct connection and control system communication function

●Meet multi-product, multi-process parameters, multi-production capacity conversion and different sterilization temperature requirements

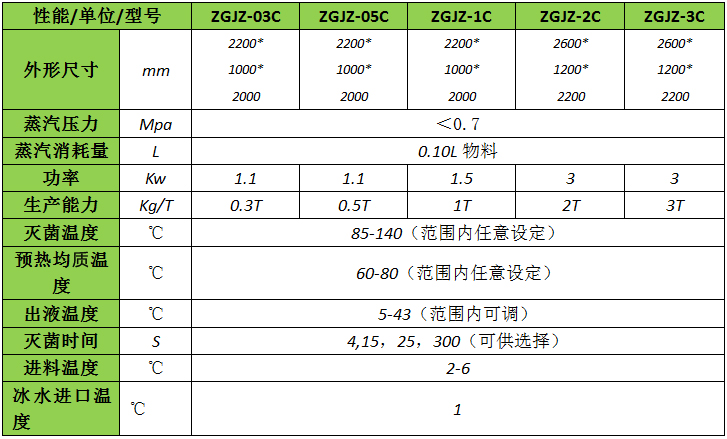

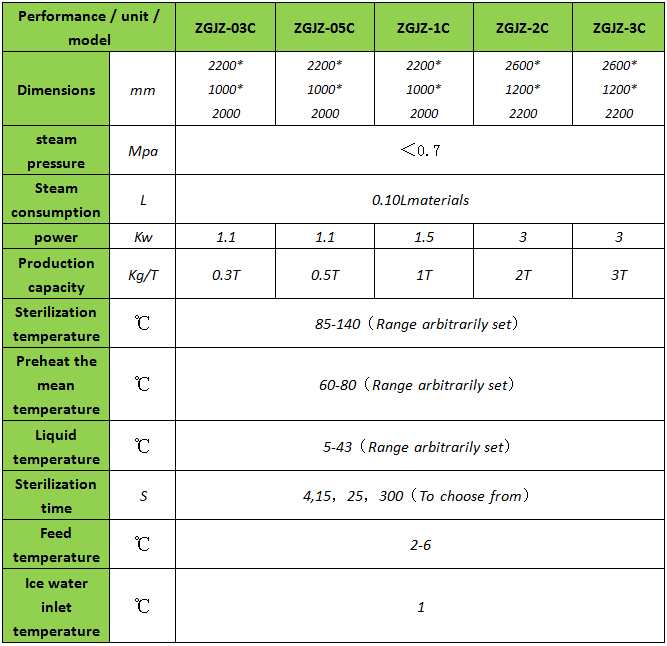

|