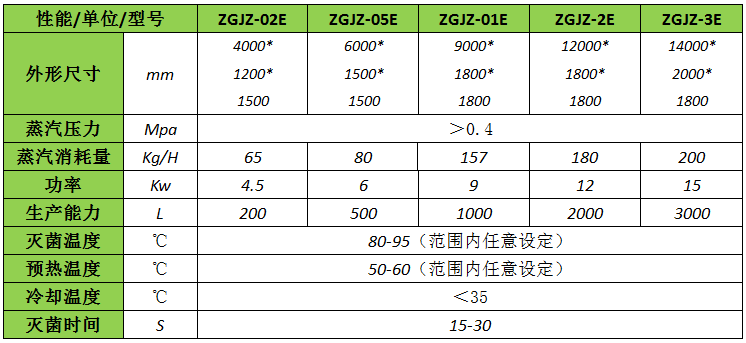

該機組廣泛用于各種液态、固态 食品飲料、牛奶、豆奶、果汁飲料、罐頭、蔬菜等包裝後的二次滅菌、冷卻三個不同的溫度段,可滿足不同生産工藝和包裝材質受熱過程中不變形、不爆瓶和生産滅菌溫度的工藝要求。

采用日本電腦程序控制器系統和配件、觸摸屏人機界面(miàn)、智能(néng)化顯示儀供客戶選擇;具有50-65℃預熱功能(néng),85-95℃連續滅菌功能(néng);20-40℃産品冷卻功能(néng);自動調節滅菌功能(néng);電磁閥組自動切換的全自動運行與監控系統。

The unit is widely used in a variety of liquid, solid food and beverage, milk, soy milk, fruit juice drinks, canned food, vegetables and other packaging after the second sterilization, cooling three different temperature sections to meet the different production processes and packaging materials heating process。No deformation, no burst bottles and production of sterilization temperature of the process requirements.

The use of Japanese computer program controller system and accessories, touch screen man-machine interface, intelligent display instrument for customers to choose; with 50-65 ℃ preheat function, 85-95 ℃ continuous sterilization function; 20-40 ℃ product cooling function; Adjust the sterilization function; solenoid valve group automatically switch the automatic operation and monitoring system.

|